The Digital Substation: Thinking “Outside the Box” Could Play a Crucial Role in the Future of Substation Automation

March 14, 2024

The future of power system substations may be redefined by the application of virtualization. At least that is what an increasing number of utilities are envisioning as they explore the opportunity for increased virtualization in substation design. In this future, there would be a significant reduction in the hardware used in substations. Instead, tasks will be carried out on cloud servers, marking a noticeable shift from the current reliance on extensive racks of hardware.

The appeal for utilities is the significant cost reduction for substation design and engineering, reduced usage of copper wiring, and the ability to easily replicate substation designs for future expansions.

“Consider that today’s substation can have 200 or more independent [hardware] boxes each performing a dedicated task,” says Jeremy Anderson, Senior Vice President of Product Development at NovaTech Automation, a leading U.S. provider of automation and engineering solutions for power utilities headquartered in Quakertown, PA. “That’s a tremendous amount of wire to pull, hardware to maintain, and it continues to become more and more congested. In a virtual digital substation, two or three servers run everything.”

With a vision for an intelligent grid of the future that is adaptive and resilient requiring less hardware and leveraging more virtualization, the utilities industry has formed the Virtual Protection and Control Alliance (vPAC) to explore how to do this. The focus is to accelerate the creation of a standards-based, open, interoperable and secure architecture to host protection, automation, and control solutions for power system substations. NovaTech is one of its over 20 member organizations.

“From our standpoint, we wanted to help define the future of substation automation,” says Anderson. With this in mind, NovaTech has spent the past year creating a virtual version of its Orion Substation Automation Platform to run on any server. The system is hosted on a host machine known as a hypervisor and servers powered by Intel CPUs.

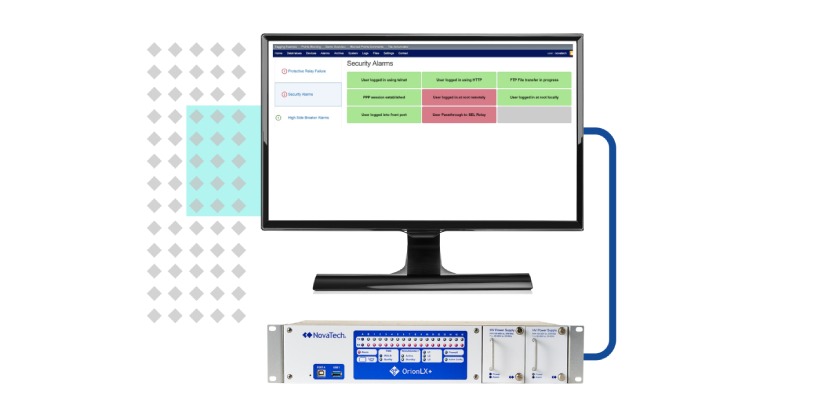

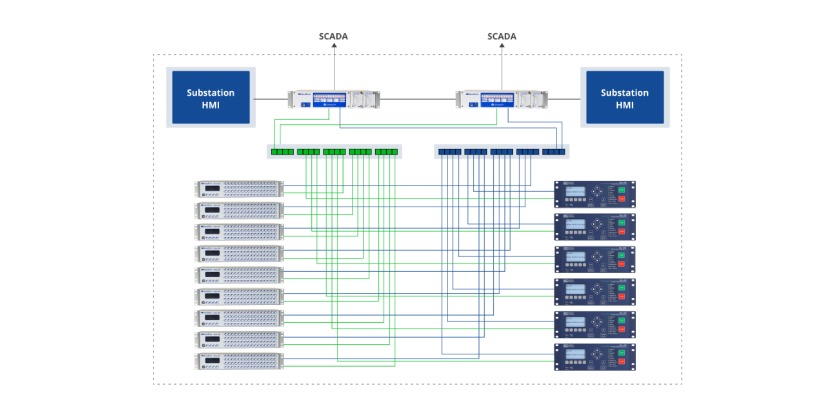

The company’s flagship product, the Orion is a communication and automation processor that can connect to nearly any substation device in its native protocol, perform advanced math and logic, and securely present the source or calculated data to any number of clients in their own protocol.

The Orion can be integrated with any equipment, including competitors, and is often connected to microprocessor-based relays, meters, event recorders, IEDs and RTUs. It is then connected to an existing enterprise network or SCADA system.

An emerging substation model

According to Anderson, there is a coordinated push by some large investor owned utilities in the United States and globally to move to what is being called the “digital substation.” Still, not all utilities are ready to pull the plug on the traditional substation design quite yet.

“Most utilities aren’t moving in this direction at this point,” explains Anderson. “But they are certainly investigating it thoroughly with the plan to move in this direction in the coming years.”

Cost savings is a leading driver of utilities’ interest in virtualization.

“It is a lot less expensive to build multiple substations once a virtual design is established because you’re not pulling tons of copper wire everywhere,” says Anderson. “When it is based on the ethernet, you can buid a substation that is somewhat cookie-cutter in design and easily replicatable. This represents a significant cost saving in substation design and engineering.

The cost outlay for hardware is also reduced. “Consider that two or three servers that cost $10,000 each can potentially replace up to 200 hardware devices that average $10,000 per device. The savings are significant even if you factor in licensing fees for virtual machines,” says Anderson.

Recent supply chain challenges are also increasing the appeal of hardware agnostic solutions.

“The pandemic certainly tested the supply chains in our sector,” says Anderson. “There were massive issues around the world trying to buy hardware, especially custom-built devices. With virtualization, if a server ever fails, it is easier to find a replacement and the utility is not limited to proprietary hardware.”

Designing the virtual system

In creating the virtual Orion, NovaTech wanted to ensure the system functioned identically to its current hardware-based system.

“The biggest challenge was taking a system that was developed over many years as embedded software for purpose-built hardware and make it run on any server,” says Anderson.

He adds that in some ways it was easier than initially thought. “The virtual Orion looks and operates the same as every unit we have sold,” says Anderson. “It just happens to run on hardware that we didn’t build.”

Anderson adds that NovaTech was intent on ensuring the customer experience was unaltered.

“Our customers know the Orion, how to program it, and how to interact with it. So one of our major goals was to ensure that whatever we do in this virtual environment, the Orion would operate identically from the customer’s perspective.”

The virtual Orion system is currently in beta test at a utility in Arizona with the full release planned in February. The company plans to debut it at the DISTRIBUTECH conference in Orlando, an annual event for showcasing cutting edge technologies in power transmission and distribution.

Looking ahead

“We are still in the early days of the deployment of the virtual digital substations,” says Anderson. “There are some early adopters, but I anticipate that we are at least five years away from broad-based market adoption.”

However there is an opportunity to solve a more immediate issue in substation environments. As more IoT devices are installed in utility distribution systems, a single virtual Orion on a server could be used to collect and manage data from thousands of sources. When all these devices must be hardwired, it can take several racks of Orions to collect all the data.

A similar scenario could drive the use of the Orion beyond the substation environment and into any enterprise where thousands of devices are collecting data.

With cloud computing and virtualization changing the contours of many industries, momentum continues to build behind virtualizing more of the work of a substation. The blueprint for tomorrow’s power system substation has yet to be fully written, but it is only a matter of time that we will see more virtual environments emerge through the collective expertise of industry stakeholders.