Eplan Platform 2024: Why It’s Worth Switching to the New Version

March 13, 2024

By Sean Mulherrin, International Solutions Architect, EPLAN

With the highlights of the new Eplan Platform 2024, Eplan continues to make engineering and circuit diagram creation as efficient and convenient as possible for users. We take a look at the most important innovations, where exactly they are in the software and how users can use the optimizations for themselves.

In our article, we take a closer look at what makes the new version (even) better than its predecessors from the user’s point of view and why a version change is worthwhile.

What’s new in Eplan Platform in 2024?

1. Enhancements in the Edit Terminal Strip dialog

2. Automatically connect spare cable conductors

3. New layers for construction

6. Calculations directly in Eplan

7. Enhancements in the 3D control cabinet design

8. Eplan Platform 2024 Conclusion

Eplan Electric P8: Making working with terminals easier

Terminals are part of an electrical designer’s daily work. The potential time savings are great if the management of terminals, terminal strips and accessories are easy to manage. This is exactly what has been achieved with the optimized terminal editor of the Eplan Platform version 2024.

Edit terminal block dialog: Optimizations and new functions

1. Insert new terminals as devices directly in the dialog

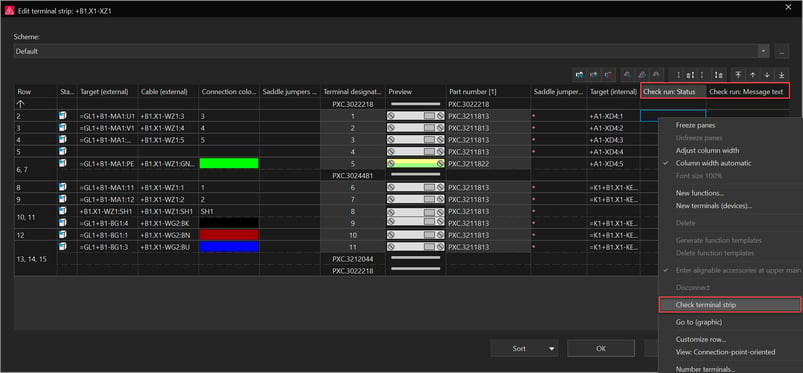

The Edit Terminal Strip dialog has been equipped with new features for more efficient processes for designers: Users no longer have to switch over to the terminals navigator to create new terminals as devices, as was necessary in previous versions. In the 2024 version, the context menu item New Terminals (Devices) is now also available directly in the Edit Terminal Strip dialog, which enables a better approach. The Create Terminals (Devices) dialog generates terminals according to a part number, defined numbering pattern and inserts them into the current terminal strip. Multi-level terminals as well as accessories are not separated.

2. Disconnecting accessories and multi-level terminals

Which brings us to the next optimization: the separation of accessories and multi-level terminals. In the 2024 version, these can be easily separated, which means that the terminals that belong together are retained when the accessories are disconnected. In the previous versions, the multi-level terminals were inevitably separated and then had to be reassembled. One more step that is no longer necessary for users of the current version. In addition, new buttons are available in the software’s toolbar, which can be used to add and edit accessories that can be arranged much faster and more conveniently.

3. Integrated validation of the terminal strip without having to leave the dialog

Another important point is to check and validate the terminal strip and, if necessary, correct errors. In the 2024 version, both steps have been optimized by simplifying user access. With the newly added context menu item Check Terminal Strip, users have the option of checking their current Terminal Strip directly without having to exit the dialog. The command opens the Check Project dialog with the preset scheme for terminal test runs, which can also be adjusted or replaced if necessary. Designers get faster results and can react faster.

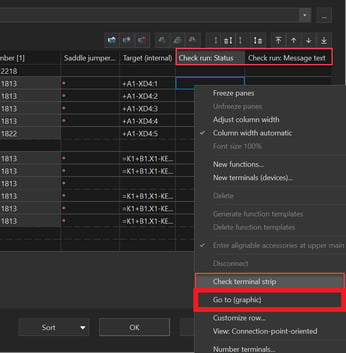

4. New jump function via “Go to Graphics”

By checking the terminal strip directly in the dialog, the designer can immediately see whether they need to go back to the schematics to make adjustments. This is a working step that is much faster in the new version 2024, as users now have access to the Go to (graphic) command familiar from other dialogs in the context menu. This closes the Edit Terminal Strip dialog and jumps directly to the selected object in the Graphical Editor, which makes it much faster to find and correct terminals.

Classic operations such as checking and troubleshooting, managing accessories and multi-level terminals, as well as creating new terminals as devices have gained significantly in performance by simplifying user access.

Eplan Electric P8: Further optimizations and functional enhancements of version 2024

Automatically connect spare cable conductors

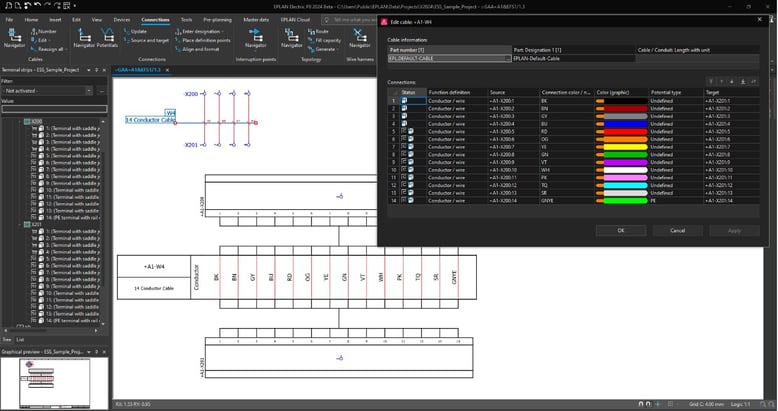

“Unassigned spare conductors” or neatly connect spare conductors at the push of a button? The former is quickly the case in the circuit diagram, for example a cable connects two terminal strips to each other, but none of the spare conductors are projected.

In version 2024, such spare conductors can be easily and cleanly handled using the new Connect Cable Connections command. If the designer launches the command, the software automatically creates and connects the spare conductors of the cables. The spare terminals required to land the conductors are also automatically generated. This not only ensures that all spare conductors of a cable are connected to spare terminal but also that errors in project planning and evaluations can also be avoided.

New layers for construction

Users now have access to additional layers in the version 2024 layer management that can be used within the framework of the electrical engineering and in the field of fluid power technology. The new layers make it possible to assign property placements and special texts or graphics to specially designated layers. This means that users can customize design notes or headings without having to change forms – ergo, an extra time saver. By practically showing and hiding notes and technical properties, transparency and user-friendliness for designers is significantly increased.

-png-1.jpeg?width=814&height=462&name=MicrosoftTeams-image%20(33)-png-1.jpeg)

Importing custom-made ribbon bars

The ribbon in the new Eplan version 2024 can easily be expanded with selected tabs, command groups or individual functions, which enables an individual and clear management of the functions in the ribbon bar. Previous adjustments in the current ribbon will be retained. The import is simply imported by right-clicking on the context menu item Import Ribbon. Command groups and tabs can be selected and imported, as well as individual commands, whereby the latter can only be inserted into a user-defined command group, similar to the previous versions. The new Ribbon Bar Action can also be used to import an entire ribbon. This will overwrite the existing customizations of the ribbon.

-png.jpeg?width=1345&height=921&name=MicrosoftTeams-image%20(29)-png.jpeg) Speaking of custom-made ribbons: In the 2024 version, external programs are also taken into account when exporting and importing the ribbon and can be inserted like any other command.

Speaking of custom-made ribbons: In the 2024 version, external programs are also taken into account when exporting and importing the ribbon and can be inserted like any other command.

Direct access to services such as Eplan Engineering Standard

In version 2024, the useful examples and templates of the Eplan Engineering Standard can be accessed directly from the software via the Eplan Cloud tab. In this way, the designer can find support much faster and without detours, which he can immediately use for his work – for example, standardization templates, application examples and best practices. The online training courses of the Eplan eLearning library as well as the software installation aids of the Guided Installation can also be accessed quickly in this way.

-png.jpeg?width=1310&height=247&name=MicrosoftTeams-image%20(32)-png.jpeg)

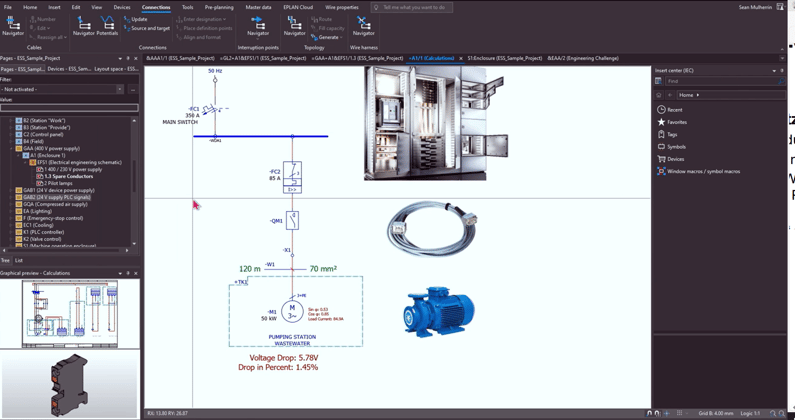

Calculations directly in Eplan

One point that Eplan users had frequently requested in the past was the possibility of carrying out calculations within the software, from which concrete project planning information can be derived. To date, such calculations have required data transfers and exports, as well as the calculations themselves having to be carried out outside of Eplan.

From version 2024 onwards, project-specific calculations can be carried out directly in the software, which saves users a lot of time, especially for short-term changes. For example, the voltage drop on a cable between a motor control center and the pump to be supplied can be calculated and verified directly in the circuit diagram thus making sure the cable size is ok for the correct functioning of the pump without detours via Excel.

Eplan Pro Panel: Enhancements in the 3D control cabinet design

Simple and intuitive navigation via navigation cube

The 3D control cabinet design, a number of software optimizations and enhancements have been added in the Eplan version 2024. Until now, it was only possible to change the views of the installation space or the view of the 3D model of the control cabinet in Eplan Pro Panel by means of commands in the status bar or by means of a key combination.

In the current version, it is possible to create arbitrary views with the help of a new navigation cube placed at the top right of the open installation space.

The navigation cube allows you to quickly and intuitively rotate and turn the 3D model with the mouse, making it easy to access views and surfaces. Users also have full control over the navigation cube itself: The start view of the 3D model for the cube can be defined just as individually as the size of the cube and whether it should be shown or hidden in the installation space. This increases user-friendliness and achieves faster results in control cabinet construction.

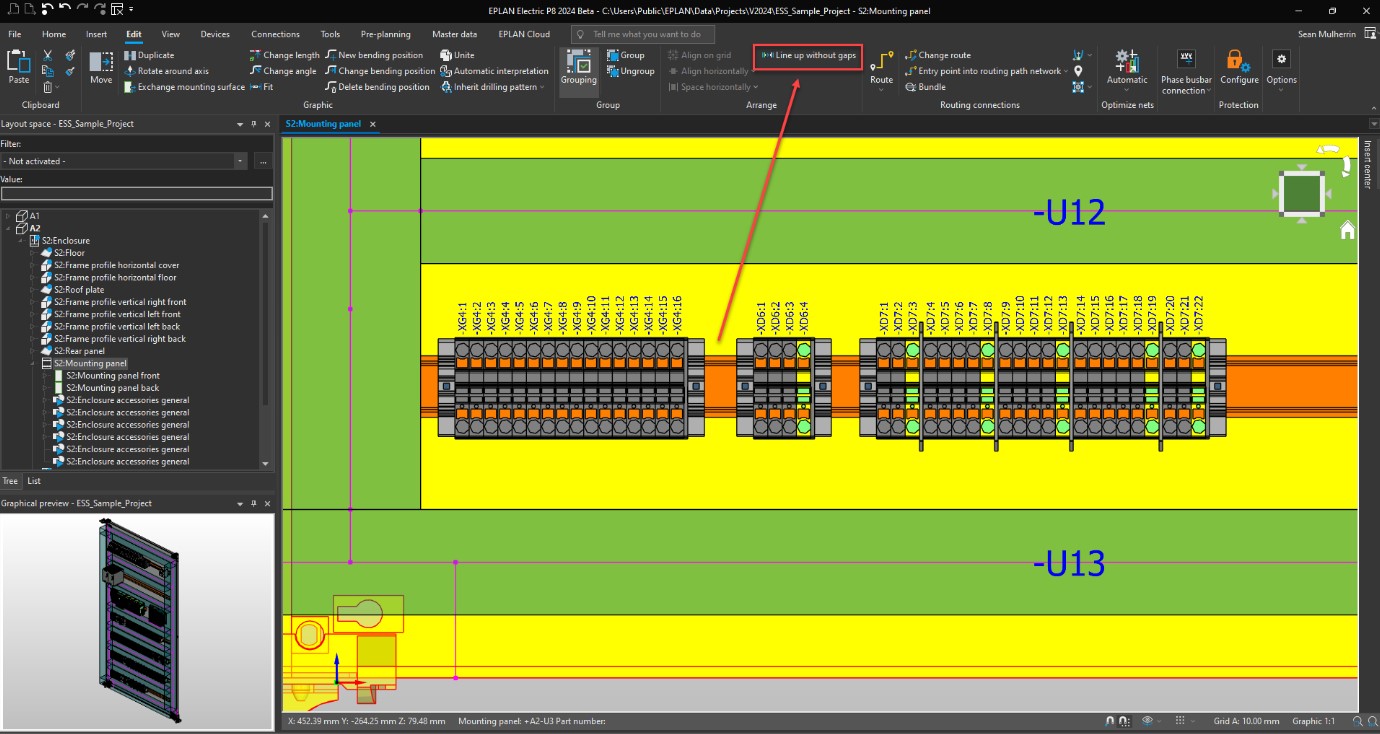

Seamlessly line up 3D article placements

Many users are familiar with this: Due to the incorrect placement or subsequent removal of assembled devices and components, gaps arise on DIN or profile rails during the 3D control cabinet construction. In the 2024 version, these can be easily closed automatically, eliminating manual rework or time-consuming postponement actions. Users can find the new Line Up Without Gaps command in the Edit tab in the Arrange command group. If the command is executed, it removes gaps and places 3D parts placements together and ensures order and overview on the DIN rail without manual effort.

Also practical: 3D part placements can be lined up at the ends of a rail – whether left or right – if there are gaps between the components and the rail end.

Conclusion: what’s new in Eplan Platform 2024

Which brings us back to the challenges in day-to-day engineering and in particular the time factor mentioned at the beginning: In engineering today, things have to be done quickly and this works best by standardizing and simplifying typical operations in electrical planning. The Eplan Platform 2024 supports users with a large number of new, practical functions and enhancements, thus accelerating the creation of circuit diagrams and 3D control cabinet construction enormously.