SEW-Eurodrive Demonstrates StarterSET for Vertical FFS Machines at ATX 2023

February 14, 2024

By Krystie Johnston

Flexible, modular, and independent

Across Canada and around the world, innumerable products are packaged, transported, and processed in a variety of ways before finally being distributed. The packaging machines that assist with this process are vitally important, and when automated, must be able to complete these tasks with various functions and movements.

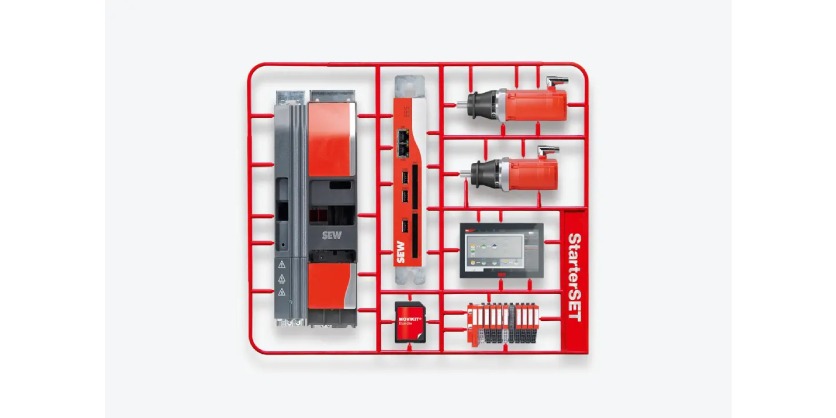

To meet these challenges, SEW-Eurodrive has developed their StarterSET, which consists of pre-selected hardware and software for specific machine types. The StarterSET offers perfectly matched and total automation packages. It can be used as is, as a basic package, or can include flexible adaptation options and countless customized add-ons.

Arne Valentin, Technology Manager – Machine Automation at SEW-Eurodrive USA, explains the StarterSET during a recent Product Showcase. Valentin says, “In the cabinet, we have our MOVI-C multi-axis inverter system. It is our very powerful motion controller that runs the whole machine in a coordinated fashion, and we have our HMI solutions with software and all the drive and control software that goes with it.”

The StarterSET is the fastest route to your finished machine

“With this solution and with our StarterSETs that are available for many target machine types – not only for sealing machines, but also end-of-line palletizing, and some other machines as well – we are really focusing on two big topics: one of them is maximizing OEE (overall equipment effectiveness), the availability of the machine in the field to reduce downtime and increase process safety,” says Valentin. The other topic he discusses later in the demonstration is how this solution addresses industry trends such as digital twin concepts and predictive maintenance.

Valentin says, “How do we do this?” The answer is what we call our ‘Power and Energy Solutions.’ This is a range of products that we integrate with our standard VFDs, and we store energy in those capacitor modules. So, whenever you are out in the field and in operation, and you lose power for one, two, five seconds – however long it is – we can power through those power outages. Instead of having the machine stop in an uncontrolled way, or the tools crash, or in this case, the paper rip, we use the energy stored in our inverters and run through that power outage. It really increases process safety.”

Machine automation solutions from start to end of line

Demonstrating this process at the show, Valentin shows how a machine used to package tea into bags is turned off. The lights go out, indicating that there is no external power to the machine. However, customers witness the machine still running via the capacitor modules.

“The cool thing is, we can define certain stop behaviours. We can say, ‘Whenever we are reaching a certain charge level, we bring the machine to a safe stop, we finish two more cycles, we produce five more bags of tea, and we stop.’ We do not damage anything. And then once we get to 20% charging level, we will do a safe stop, and make sure nothing gets damaged. It is a really flexible approach,” says Valentin.

“The other really neat thing about this power and energy solution is, that when you size your application, you need to bring power to the machine, and that is usually done by sizing everything according to peak power. However, by using capacitor modules, we are using the peak power for the machine. If a big axis is accelerating through the capacitor, we can downsize the in-feed, downsize cable sizes, downsize the fuses, and really keep things very streamlined and small for the in-feed. We are running everything through those capacitors: safety, 24 Volts, all of it,” he adds.

Having covered how the StarterSET improves overall equipment effectiveness, Valentin moves on to demonstrate how this solution addresses industry trends. “A lot of OEMs and end users talk about digital twin concepts and predictive maintenance, and we have a great solution for this.”

The right solution for numerous requirements

Valentin explains, “Whenever we size this machine, or size the different axes, for example, we know how much power we expect out of the motor at any time of the machine’s operation. So, when we size this using our sizing software, we know what we expect to happen. And then, when we run the machine, we see what the inverters are actually putting out as current value, and we can compare the two. It is a very simple calculation.”

Demonstrating this to the customers while the machine is running, he takes live values, the set-point and the actual torque, and notes how these values can be compared. He says, “Whenever you see 10% more power than we expect, something might be mechanically wrong with this machine, and we can tell the operator, ‘Check your springs, or check your belt. Something might be damaged.’ And this is what we are doing here. When we are moving the sealing elements up and down, there is actually a spring helping with the motion, and through our inverters we are picking up the spring oscillations. It is very high-quality measurements that our standard hardware can pick up.”

To summarize, StarterSETs are a great way of making sure that components work well together, that the software works well together, and SEW-Eurodrive offers that for multiple types of machines including the sealing machine demonstrated at the show. Their solution addresses a lot of industry trends, like energy efficiency, process safety, and overall equipment effectiveness. SEW-Eurodrive is so much more than gear motors.