ABB: IRB 930 SCARA Robot to Transform Pick-And-Place and Assembly Operations

December 14, 2023

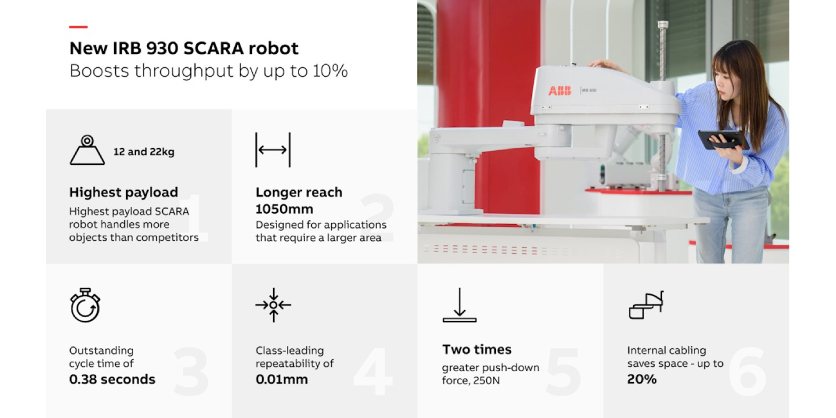

ABB Robotics is expanding its industrial SCARA robot portfolio with the addition of the IRB 930.

The new robot, compromising three variants capable of handling 12 kg and 22 kg payloads, has been designed to meet the demands of new growth opportunities in traditional and new markets.

“Our latest SCARA addition broadens our portfolio, offering our customers even more automation choices,” said Marc Segura, President of ABB Robotics. “Whether 3C, automotive electronics, electric vehicle battery cells or solar panels, our new IRB 930’s higher payload and longer reach brings the performance advantages of our wider SCARA range to new and traditional segments alike. With the global SCARA market predicted to grow to $15.54 billion by 20271 at a compound annual growth rate of 14.4%, the IRB 930 positions ABB well for growth.”

Marc Segura, President of ABB Robotics

Engineered for fast point-to-point tasks that demand high payloads and large work areas, the IRB 930 has three variants capable of providing the highest payload of any SCARA robot in its class. In addition, the 22kg variant delivers a 10% increase in throughput by handling more and heavier workpieces at once. The IRB 930 also provides an exceptional 200% increase in stronger push-down strength (with a maximum downward force of 250N) making it ideal for force-intensive operations such as screw-driving and assembly tasks required when working with components such as battery cells, display panels and solar modules.

ABB’s OmniCore controller will power the new IRB 930. The OmniCore controller offers best-in-class motion control through TrueMove and QuickMove alongside built-in digital connectivity and scalable functions. The motion control delivers an impressive cycle time of 0.38 seconds, with a repeatability deviation position of only 0.01 mm. This performance empowers the IRB 930 to enhance hourly production rates while upholding high-quality manufacturing standards.

The new IRB 930, along with the IRB 910INV, IRB 920 and IRB 920T, completes ABB’s range of SCARA robots to customers with a three kg to 22 kg payload requirement. These high-performance SCARA robots are designed for use in various industries such as packaging and manufacturing where high speed and high repeatability pick-and-place and assembly operations are required.