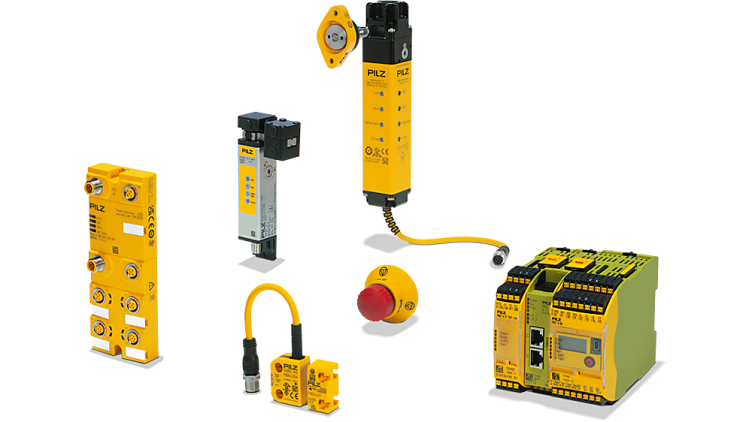

Pilz: PDP67 IP67 Modules – Cabinet-Free Installation to Connect Safe Sensors Directly

October 22, 2024

With the PDP67 modules, Pilz offers solutions for decentralised applications directly in the field. The modules have protection type IP67, meaning they are resistant to dirt and water. The decentralised modules optimise installation and wiring work. They save time, money and space in the control cabinet.

As they are integrated into dirt and water-repellent IP67 housings, the PDP67 modules reliably ensure safety even in rugged industrial environments.

Connect safe sensors directly

PDP67 modules are used directly in the field, and forward signals from the sensors connected decentrally in the field to the safe small controller PNOZmulti 2.

Pilz is expanding its product portfolio for decentralised applications with the input and output modules PDP67 F 10DI4DO 5/8 ION (VA). The PDP67 modules have ten safe digital inputs and, as a new feature, have four safe semiconductor outputs, which enable the modular safety gate system PSENmlock to be connected directly, for example. You configure your safety circuit in the software tool PNOZmulti Configurator. You can connect up to four of the modules with protection type IP67 to the PNOZmulti 2 via the link module PNOZ m EF PDP-Link.

Up to four safe sensors per PDP67 module – so a total of up to 64 sensors- can be monitored flexibly in the field in this way. A version with stainless steel screw connections is available, for use in the food industry. M12 plug-in connectors, two 5-pin and two 8-pin, link sensors and actuators quickly and easily to the PDP67 module.

- Complicated wiring is avoided

- Reduces costs when expanding and commissioning modular production plants

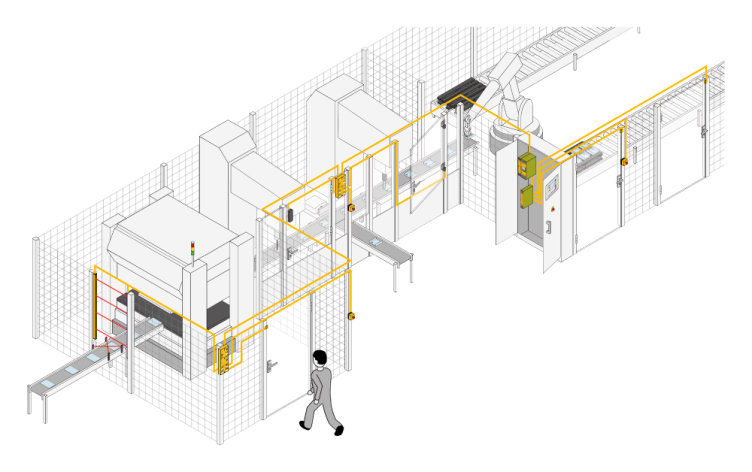

Decentralised safety for modular plants

Flexible and modular automation solutions require I/O systems that offer personnel and process protection directly at the point of danger. The new PDP67 PN with Profinet/Profisafe interface enables exactly that. Thanks to the IP67 protection type and robust zinc housing it is ideal for positioning on the machine, outside of the control cabinet. It provides reliable safety even at temperatures of -30°C to 70°C!

The I/O module is simple to configure and can easily be integrated into existing Profinet/Profisafe networks. The absence of control cabinets and the use of simple M12 plug-in connectors reduces the wiring work significantly. That saves time during commissioning and enables modular production plants to be expanded with ease. Thanks to universal connections, which can be configured as both inputs and outputs, users only need to keep one type of PDP67 PN in stock. That saves additional space in the warehouse!

Simple installation of IP67 modules – Your benefits

- Less planning and design work, thanks to simple installation

- No control cabinet necessary

- Enables a modular machine concept

- Can be used up to protection type IP67

- Reduced wiring

Features of IP67 modules

- Reduced wiring due to plug-and-play with standardised M12 plug-in connections

- Installation almost anywhere due to compact and robust housing

- Decentralised installation of safety-related, digital sensor and actuator technology

- Simple configuration due to proven PILZ tools

- Integrated web server for rapid fault diagnostics (PDP67 PN)

- Universally configurable, safe inputs/outputs (PDP67 PN)

- Application in heights up to 5,000 m

Decentralised and passive – decentralised safety

Modules with Profinet / Profisafe enable simple configuration and installation in Profinet/Profisafe networks. They expand our PDP product range and can be integrated into the network of remote I/O systems PSSuniversal 2. Sensors as well as actuators can be connected to an IP67 device thanks to flexibly configurable I/O ports. As such the device is highly flexible for use in the most diverse applications. It also simplifies your stockholding! Thanks to the robust, zinc housing it withstands temperatures of -30° to 70°C.

The passive junction PDP67 F 4 code enables the connection of up to four sensors PSENslock or PSENini. As well as being able to connect to the configurable control systems PNOZmulti, PNOZmulti Mini and PNOZmulti 2, safety relays PNOZsigma are also available.

Digital PDP67 modules with protection type IP67 forward signals from the sensors connected decentrally in the field to the evaluation device on the small controllers PNOZmulti 2. Up to 64 sensors and actuators can be connected. Complicated wiring is avoided. That way you reduce costs during commissioning and when expanding your machinery and production plants.